PRODUCTION PROCESS

For a smooth ordering process, we offer you the following steps to ensure a seamless experience.

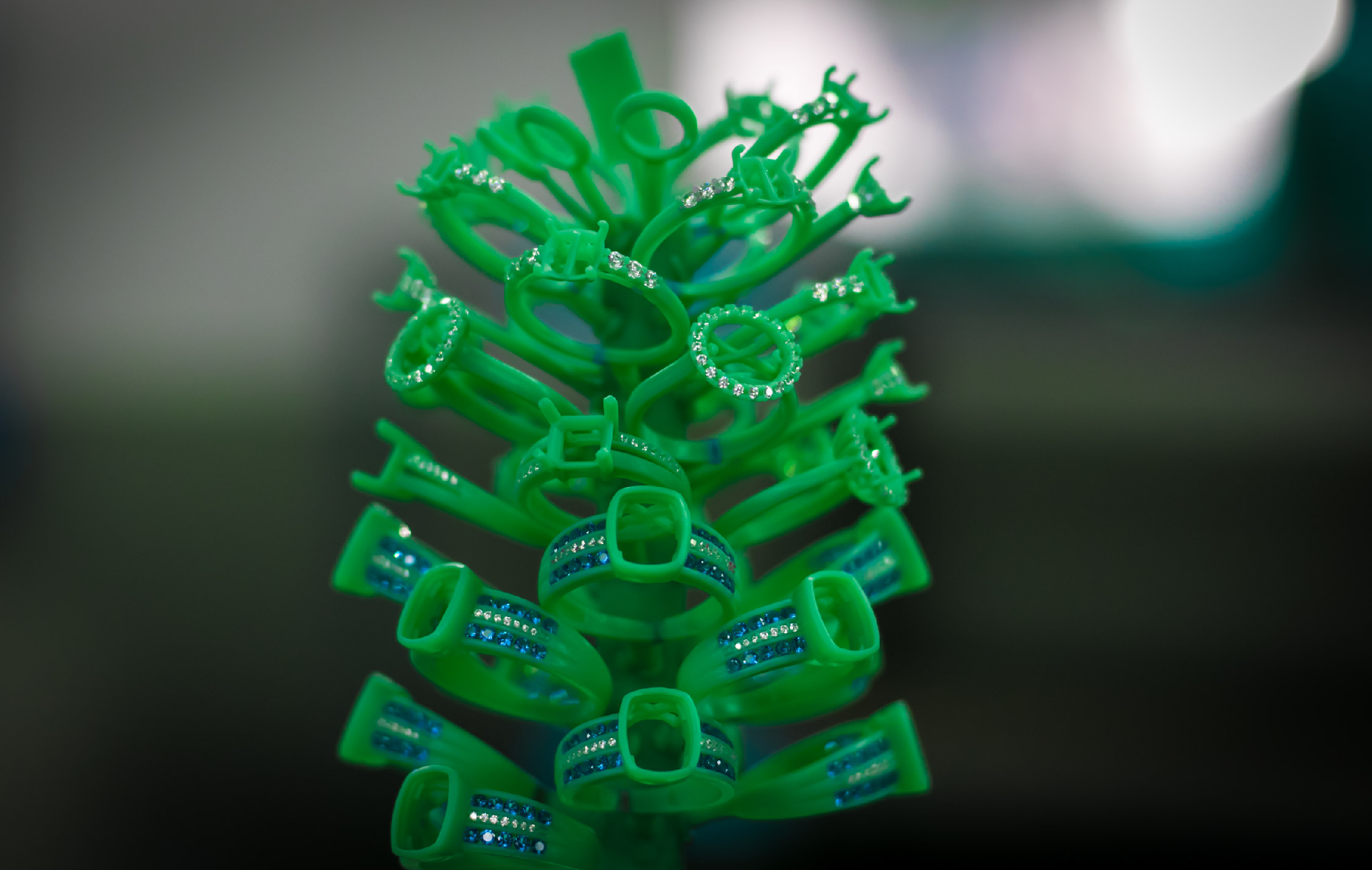

Creating a wax sample

First, we create a model from wax by pouring heated wax into the rubber mould to create wax replicas of the designs.The stones will be attached to each model, depending on the designs. And then each of these model will be attached to a branching wax tree to cast multiple jewelry pieces at the same time.

Plaster pouring

The wax tree is then placed in a cylinder which is then filled with liquid plaster, ready to be put in the oven.

Roasting the cylinder

After all the wax is burnt away in the oven, the plaster mould is left behind with void in the shape of the wax tree.

Preparing gold and alloy

Raw gold and other metals will be prepared beforehand by the exact ratio of the order. The gold and alloy is then melted, ready to be poured into the plaster mould. The cylinder will then be left to cool, inside is a metal tree with rough forms of the jewelry pieces attached to it.

Metalwork

The pieces will be detached from the tree and buffed to achieve a smooth surface. Then, the finishing stages such as soldering, texturing,… will be performed to achieve the desired look.

Stone setting

After that, we will then place and secure the gemstones into their mounts to complete the jewelry piece.

Polishing

After the metalwork, the piece undergoes thorough polishing to achieve a brilliant shine and remove any surface imperfections such as scratches or bubbles...

Plating

Next, a thin layer of metal is applied to the surface of a piece to enhance color and durability, prevent tarnishing, giving the piece a luxurious look.

Quality control

Finally, the jewelry will be examined for any defects, such as imperfections in the metal, misaligned stones, or inconsistencies in the finish. Any issues are addressed and corrected to ensure that the piece not only looks exquisite but also meets the standards for wearability and longevity.

ORDERING PROCESS